DISCOVER OUR CUTTING-EDGE SAFETY APP FOR RISK MITIGATION

SEE HOW JT THORPE SAFETY KEEPS YOUR PROJECT SECURE

Uncover the cutting-edge safety app developed by JT THORPE that revolutionizes risk mitigation and ensures a safe project environment. Witness the comprehensive features and functionality of JT THORPE Safety that enable real-time reporting, hazard analysis, safety documentation review, and proactive risk reduction, keeping your project secure and your team protected

Innovative Scaffolding Design Solutions

Experience Virtual and Augmented Reality with our Advanced Scaffold Design App

With the utilization of Avontus software, JT THORPE provides cutting-edge scaffolding design services, offering 2D and 3D renderings as well as immersive Virtual Reality (VR) experiences and Augmented Reality (AR) views, allowing you to visualize and navigate your scaffolds before construction begins.

EXPLORE OUR REVOLUTIONARY SCAFFOLDING TRACKING APP

WITNESS THE POWER OF JT THORPE INSPECT IN ACTION

Discover how JT THORPE’s revolutionary scaffolding tracking app, JT THORPE Inspect, empowers you with real-time tracking, detailed reporting, and seamless project management. Experience the convenience and efficiency of our innovative app that transforms the way you track and manage your scaffolding projects.

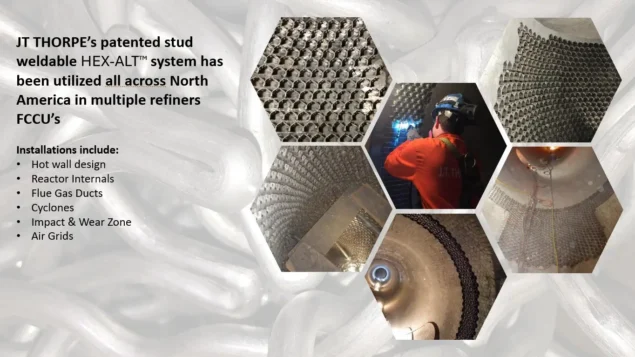

HEX-ALT™: Refractory Anchoring Redefined

Patented Precision for Peak Performance

JT Thorpe’s patented HEX-ALT™ anchor and refractory anchoring system and process are protected under US Patent Nos.10,857,616 and 11,850,688. Both patents describe JT Thorpe’s proprietary HEX-ALT™ anchor, a plurality of HEX-ALT™ anchors, and a method of installing a plurality of HEX-ALT™ anchors in a hexagonal pattern. The HEX-ALT™ anchor comprises a singular folded metal plate comprising a stem that comprises at least one triangular section to be welded to a backing surface and a folded stem base and a branch section comprising two branches, wherein the singular metal plate is folded together at the stem base, such that the stem of the HEX-ALT™ anchor is twice as thick as the two individual branches.

The HEX-ALT™ anchors arranged in a hexagonal pattern and the process of applying the plurality of HEX-ALT™ anchors to a backing surface are patented under US Pat. No. 10,857,616.

The individual HEX-ALT™ anchor and the combination of the HEX-ALT™ anchor and ceramic ferrule are patented under US Pat. No. 11,850,688.

Advanced Heat Induction Welding Solutions

Efficient and Reliable Welding with Induction Technology

Our team employs state-of-the-art heat induction welding techniques, enabling fast and effective preheating of steel and direct stud welding of anchors onto the material. This advanced technology ensures efficient and reliable welds, enhancing project timelines and structural integrity.

Hydro Demolition

Fast and Safe Refractory Removal

Our team utilizes advanced hydro demolition techniques to swiftly and safely remove refractory materials. By employing high-pressure water jets, this method eliminates the need for manual chipping, ensuring enhanced safety and significantly accelerating the removal process. With speeds 4-5 times faster than traditional methods, our hydro demolition technology maximizes efficiency and minimizes project timelines.

Robotic Arm Demolition & Descaling

Safer, Faster, Better: Next-Gen Refractory Demolition

JT THORPE uses robotic arm technology for the safest, most efficient buildup removal and demolitions. We’ve partnered with European-based G Leonard Ltd to provide Robotic Arm Descaling services to North America. The Brokk Robotic Arm Descaler, designed for challenging industrial applications, offers remote-controlled precision, allowing operators to work from a safe distance. It can operate in extreme heat, enabling early internal work.

This robotic descaler is faster than manual methods, reducing facility shutdown times. It eliminates the need for scaffolding and explosives, enhancing safety and efficiency. Its compact design allows it to maneuver in tight spaces, improving versatility and protecting workers from dust exposure and overhead hazards.