Painting and Coating Services

Comprehensive Solutions for Industrial and Commercial Applications

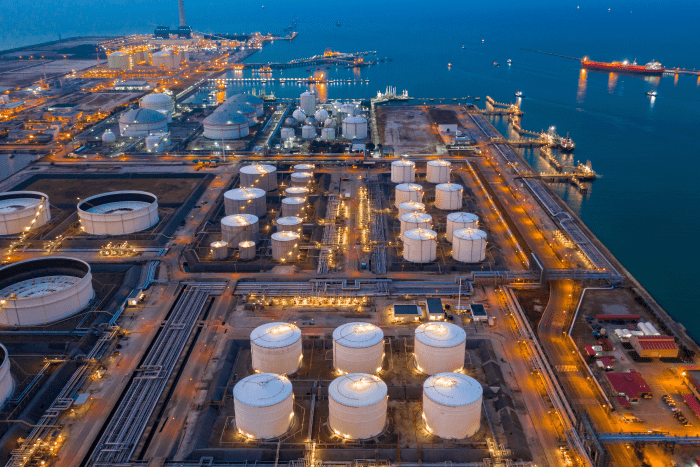

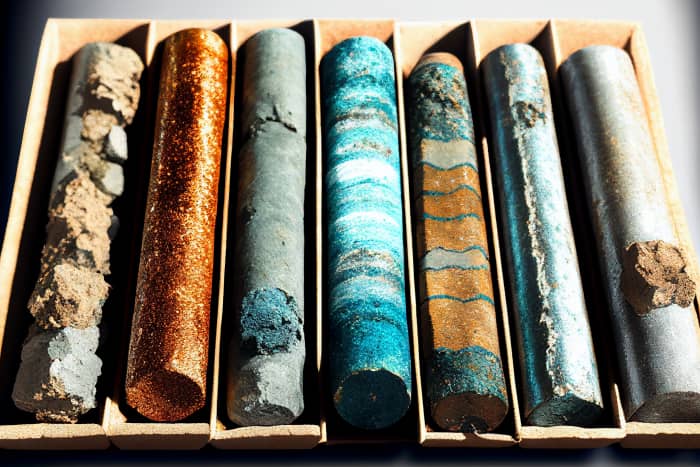

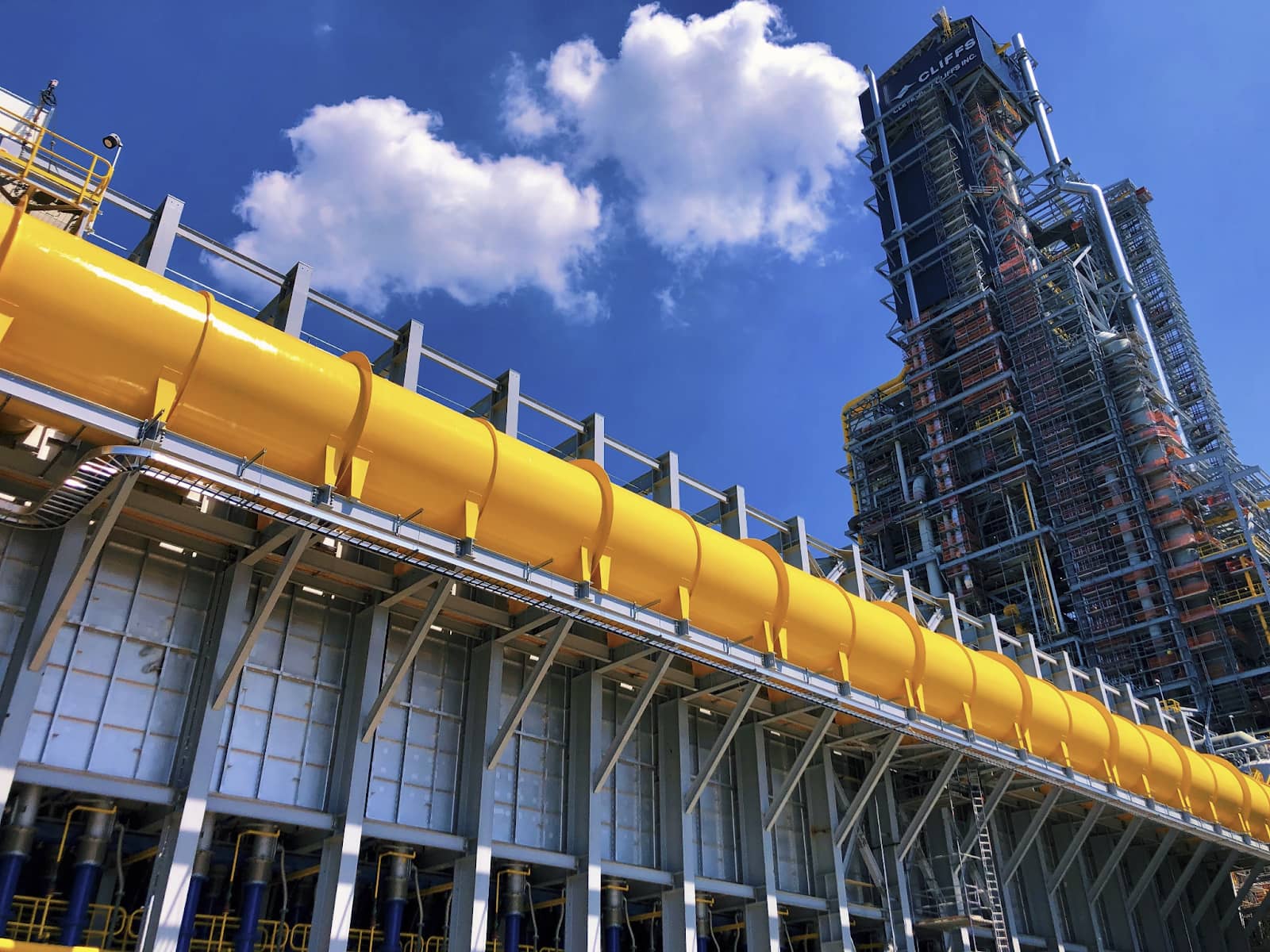

Our team offers professional painting and coating services for industrial and commercial projects. With expertise gained as a refractory contractor in diverse industries, we excel in services like lead abatement, abrasive blasting, linings, and coatings.

We Specialize In

Certificates