Expert Refractory Services for Superior Industrial Performance

Our project management is second to none

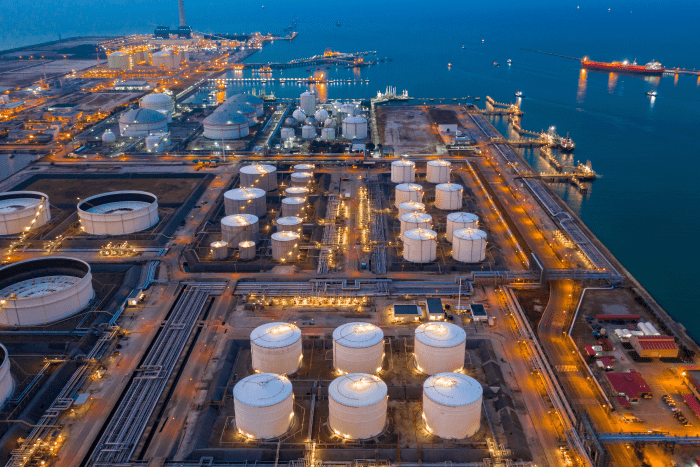

Discover the Expertise of JT THORPE, the Leading Refractory Contractor in the United States. From Refractory Lining Installations to Engineered Solutions, we serve diverse heavy industries. Whether you need new construction, routine maintenance, or enhanced efficiency, our experience, exceptional quality, and unwavering commitment to safety ensure the performance you desire.

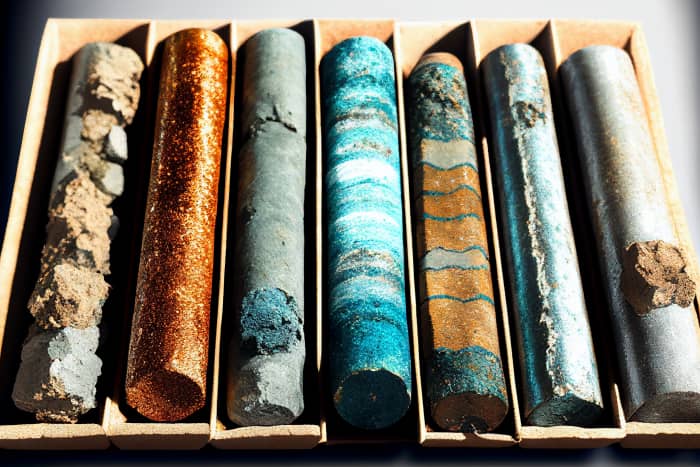

ENGINEERING AND FABRICATION SERVICES TO MEET ASME STANDARDS

Our Experience as the oldest and largest refractory company shows

JTT specializes in the fabrication and assembly of refractory, into custom shapes, linings, or components that are designed to withstand high temperatures and harsh environments in industrial applications. This process includes the selection of appropriate engineering, materials, precise cutting, followed by meticulous installation or construction to provide thermal insulation, corrosion resistance, and durability in furnaces, kilns, reactors, and other high-temperature industrial equipment.

Our Process

Detailed procedures ensure meticulous planning and execution of refractory projects.

Design Specifications tailor the refractory solutions to meet the unique requirements of each project.

Quality Control measures ensure adherence to strict standards and deliver superior performance and durability.

Expert Installation by our skilled team guarantees precise and efficient implementation of refractory systems.